Secabo provides all operating instructions and manuals online in several languages:

In the Secabo Media Centre you will find product photos and many other materials in original resolution.

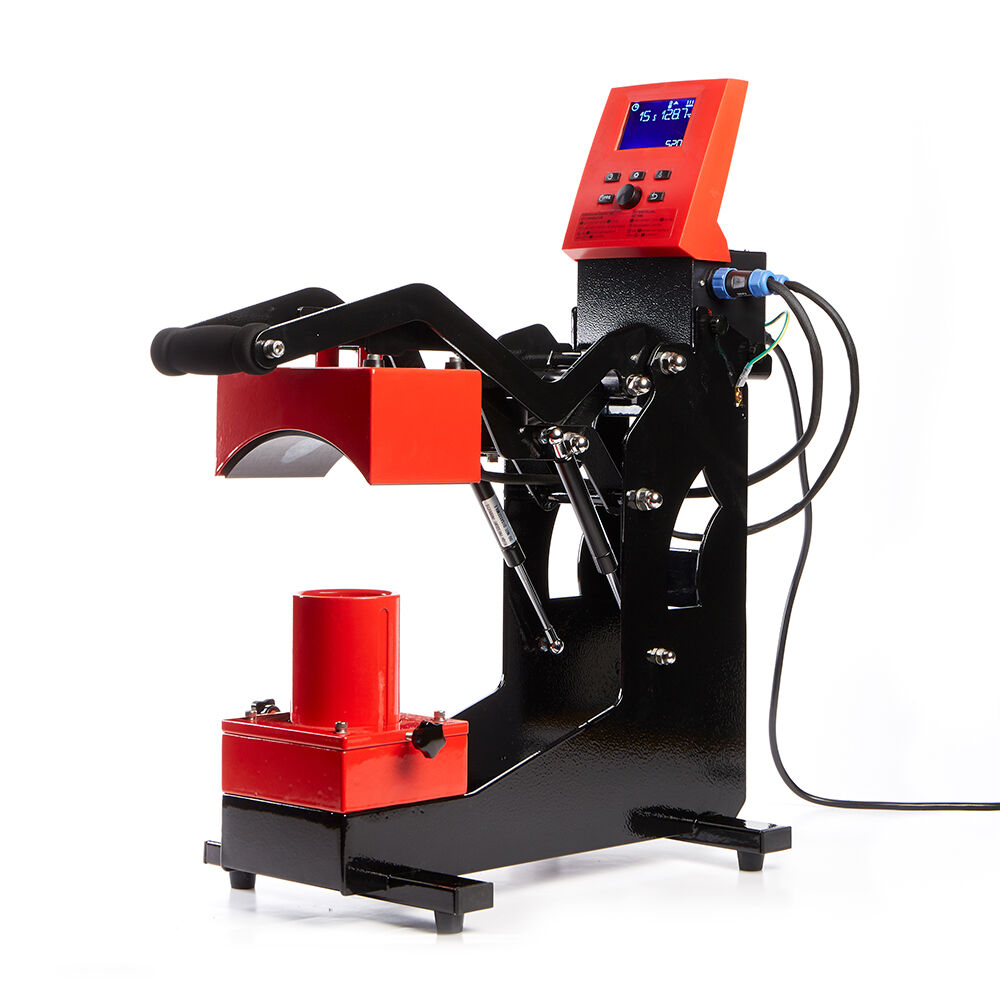

Play in the premier league with the new ball press from Secabo - With the new TCB SMART ball press, Secabo is opening up innovative ways to achieve even better ball finishing performance.

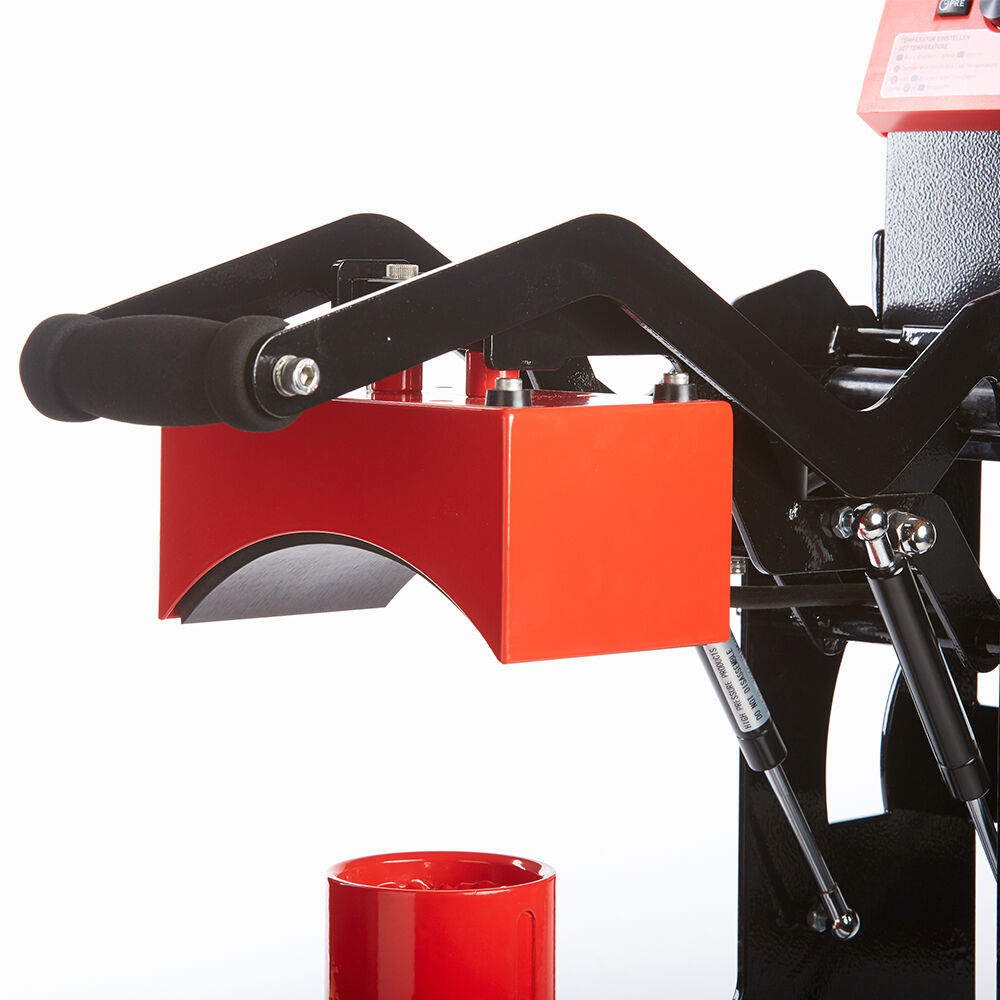

This Heat Press enables you to finish most inflatable sports balls, including artificial leather footballs, handballs and basketballs, in just a few simple steps. Even a football can be customised with a logo, player name or number using the Secabo TCB Smart Ball Press. Personalised souvenirs and prizes for events or give-aways can be produced with single or multi-coloured transfers.

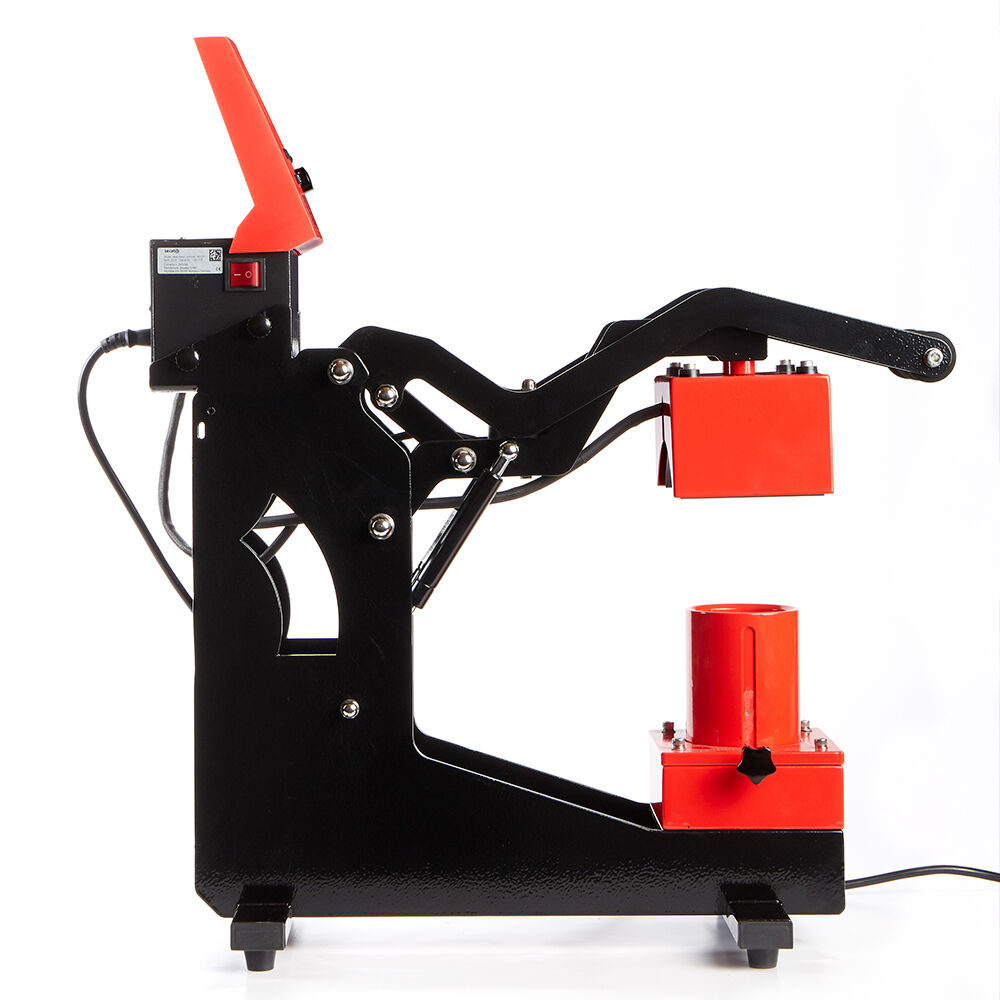

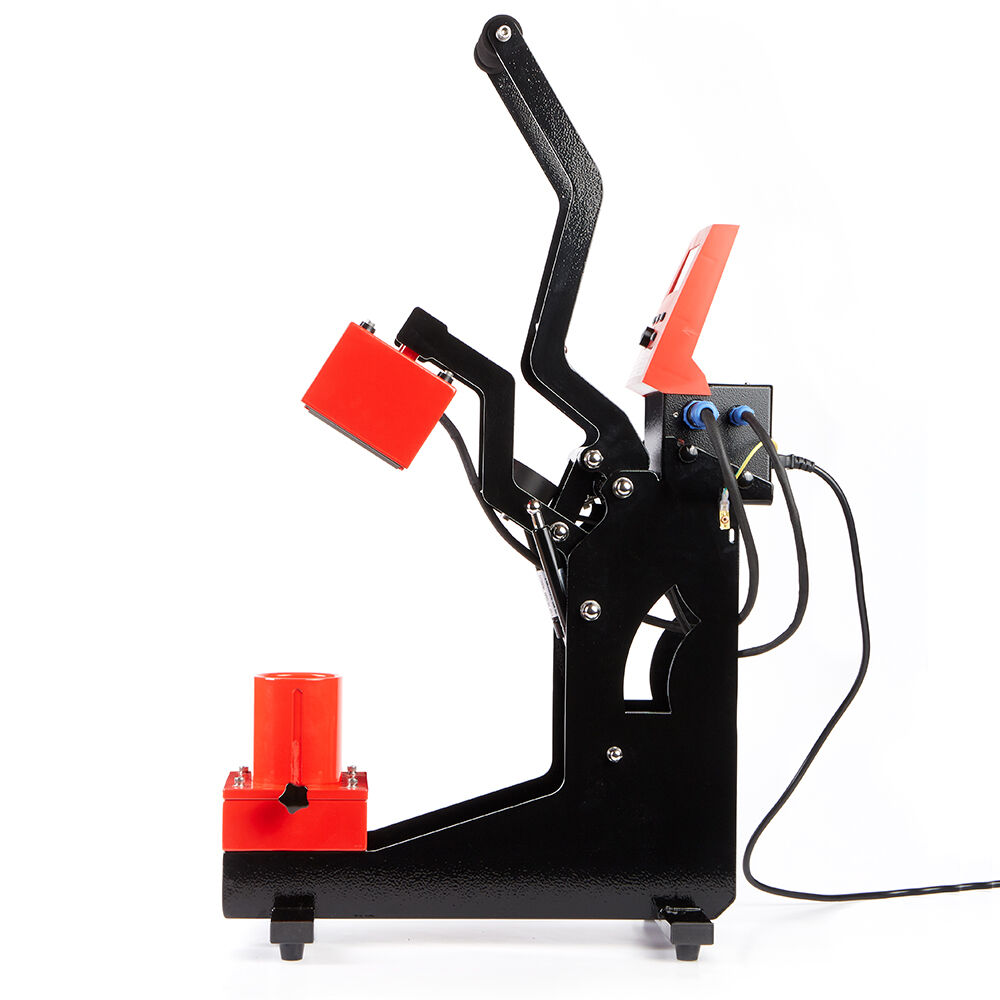

All balls can be pressed at the same temperature of 113 °C for 8 seconds. The low temperature is important to avoid damaging sensitive plastics or artificial leather. We recommend a transfer size of up to 5 cm x 8 cm so that the foil lies smoothly on the curved surface of the ball. The contact pressure of the new TCB SMART Heat Press for balls from Secabo is adjusted on the underside by pressing the cylinder downwards and adjusting it with the two screws on the left and right. The specially shaped heating plate fits almost all ball sizes and shapes. The adjustable cylinder ensures that the pressure can be adjusted as precisely as possible to the ball size. The automatically opening ball press has a large opening angle and a button for manual opening before the set time has elapsed. It is suitable for the professional use of all common heat transfer processes such as flock foils, flex foils, sublimation, transfer, inkjet flex, etc. The ball press has a digital temperature and time display. Additional functions such as the calculation of heat-up times and warning functions, in combination with the Secabo app, make this a valuable aid for all common heat transfer processes.

| Application: | Balls |

|---|---|

| Features: | auto open press |

| Series: | TCB |

| Technology: | Bluetooth, Smart |

| Abmessungen offen | 32 x 92 x 60cm |

| Abmessungen geschlossen | 32 x 71 x 70cm |

| Größe Arbeitsfläche | 5 cm x 8 cm |

| Lieferumfang | Mechanische Basis mit Heizelement, Controller Box, C13 Kaltgeräte-Anschlusskabel, Werkzeug, Bedienungsanleitung |

| Druckeinstellung | Höhenverstellung der Heizplatte mittels Handrad |

| max. Anpressdruck | 250 g/cm² |

| max. Temperatur | 220 °C |

| max. Zeitvorwahl | 999 s |

| max. Öffnungswinkel | 40 ° |

| Stromversorgung | Wechselspannung 230V / 50Hz - 60Hz, 1,00kW |

| Umgebung | +5°C - +35°C / 30% - 70% Luftfeuchtigkeit |

| Gewicht ohne Verpackung | 25 kg |

| Gewicht mit Verpackung | 31,60 kg |

| Marke | Secabo |