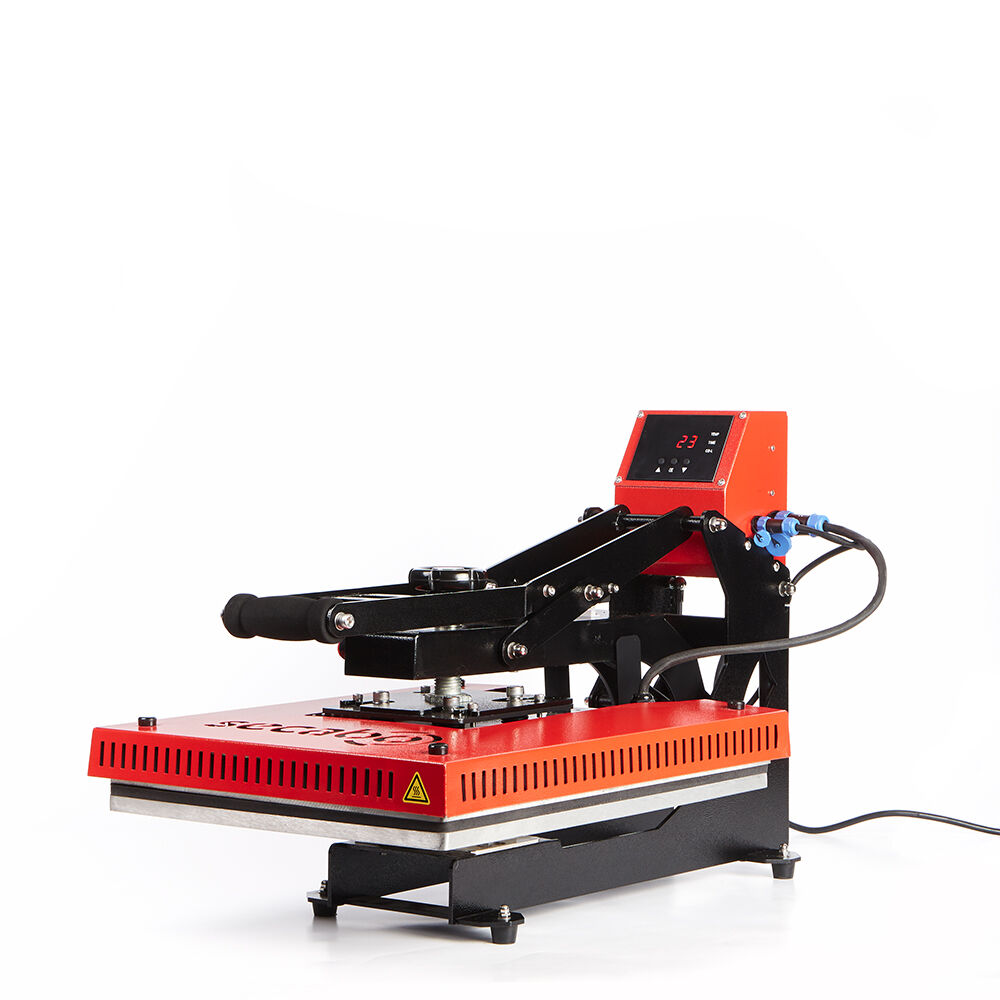

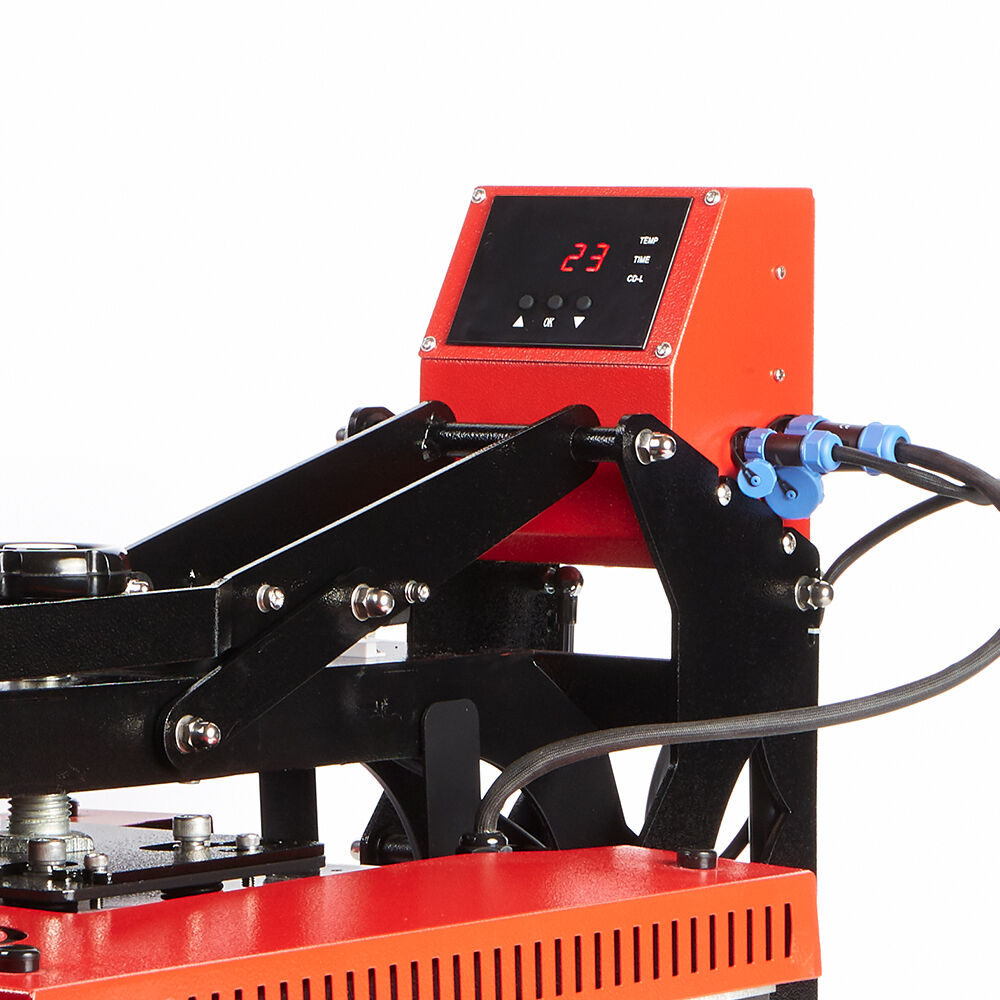

Best performance and high convenience with the Secabo LITE series - With this new development of the successful Secabo TC7 toggle press, Secabo is launching a lucrative modular system on the market that opens up a wide range of new possibilities for users. A plus in flexibility thanks to easily interchangeable components, in short a basic product with great upgrade options. The new LITE models therefore have the advantage of being able to retrofit individual base plates or heating platens at low cost and easily replace components as required. The TC7 LITE Heat Press from Secabo is a modular, automatically opening toggle press. The user does not have to wait next to the press during transfers, but can carry out other activities. Once the set time has elapsed, the press opens automatically and announces this three seconds in advance with an acoustic signal. The pressing process can be interrupted at any time at the touch of a button - for example to pre-press textiles. The temperature and pressing time are conveniently preselected using a digital controller. The contact pressure is set using a large handwheel on the top of the heating plate. The TC7 LITE Heat Press, with a working surface of 40cm x 50cm, has an additional cover plate on the heating plate to protect the user from burns. The design of the TC7 LITE is fully modular; the control unit, heating plate, base plate and base frame can be removed and replaced in a few simple steps. This also allows the use of other heating plates, for example. The LITE Heat Presses offer everything that makes textile transfers with Secabo so convenient. All professional applications of common heat transfer processes such as flock foils, flex foils, sublimation, inkjet flex, etc. are of course possible. The Secabo TC7 LITE can be optionally equipped with interchangeable plates in various formats - including a membrane base plate, a quick-change system and a slide extension for use as a double plate press. You also have the option of upgrading the TC7 LITE to our Secabo TC-SMART series.

| Application: | Textile |

|---|---|

| Features: | 40x50cm heating plate, auto open press |

| Series: | TC7 |

| Technology: | Lite |

| Abmessungen offen | 43cm x 93cm x 74cm |

| Abmessungen geschlossen | 43cm x 57cm x 75cm |

| Größe Arbeitsfläche | 40cm x 50cm |

| Lieferumfang | Mechanische Basis, Heizplatte und Basisplatte, LITE Controller Box, C13 Kaltgeräte-Anschlusskabel, Werkzeuge, Bedienungsanleitung |

| Druckeinstellung | Höhenverstellung der Heizplatte mittels Handrad |

| max. Anpressdruck | 250 g/cm² |

| max. Temperatur | 225 °C |

| max. Zeitvorwahl | 999 s |

| max. Klappwinkel | 40 ° |

| Stromversorgung | Wechselspannung 230V / 50Hz - 60Hz, 1,80kW |

| Umgebung | +5°C - +35°C / 30% - 70% Luftfeuchtigkeit |

| Optionen | Schnellwechselsystem, verschiedene Wechselplatten, Slide-Erweiterung, Membran-Basisplatte, TB7 Thermobase |

| Gewicht ohne Verpackung | 39 kg |

| Gewicht mit Verpackung | 46,60 kg |

| Marke | Secabo |

Bedienungsanleitung Media Center